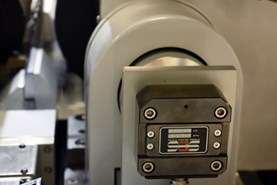

Grinding Wheel Balancing System

Grinding wheel balancing system. Then take a small object and tap the wheel. Developed specifically for use in high-precision grinding machines the customized balancing heads can compensate the unbalance of the grinding wheels. First ring your wheels - here you have to take your wheel off and tie a piece of rope or twine through the center so the wheel can dangle in mid-air.

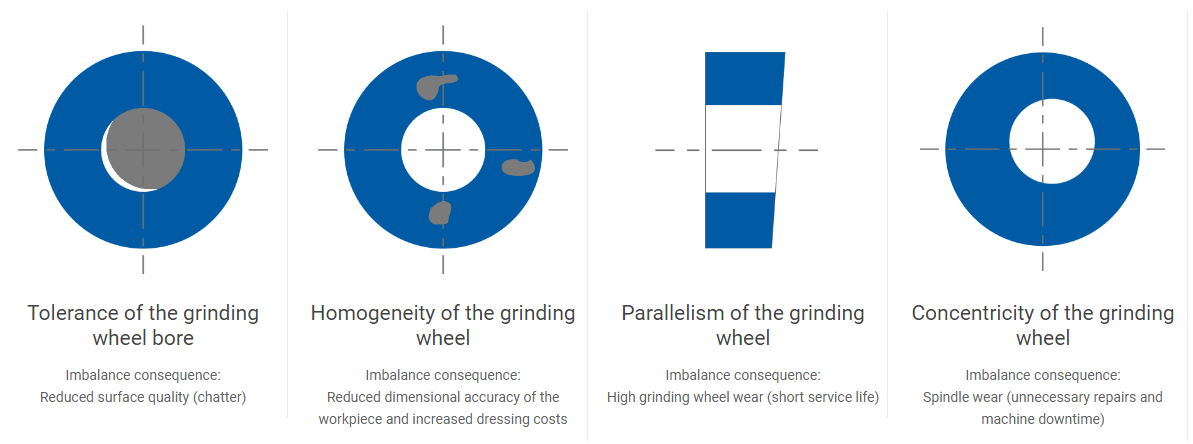

A grinding wheel that is out of balance will have greater vibration and instability and result in uneven surfaces on the parts. Grinding wheels are sensitive to vibration due to their mass and speed. Wheel out of round.

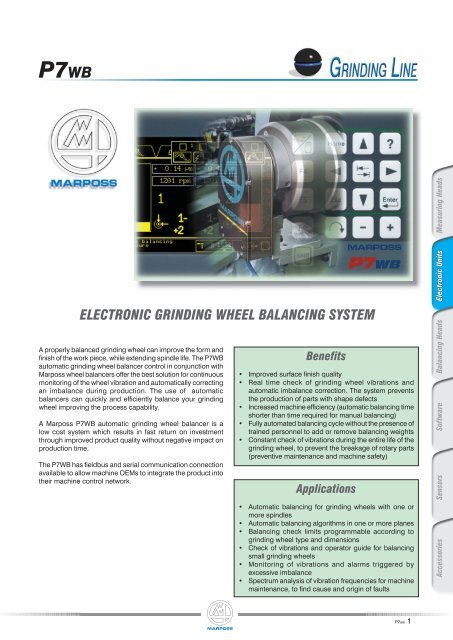

Our Balancing Machines Are Used In Motor Fan Automotive Energy Shipbuilding Mining. The bearing is abnormally worn. Based on the application and the type of balancing head the P7WB can be used with single or multi-spindle grinding machines and it can perform the following functions.

Mark the position of the adapter on the arbor remove the wheel and re-balance. In a method and an apparatus for balancing a grinding wheel balancing weights on the grinding wheel remain secured to the grinding wheel in an unbalance measuring operation and the positions at which the balancing weights are secured to the grinding wheel are stored. Thickness side to side variation of the wheel.

Ad Balancing Equipment Engineered For All Applications Parts And Production Rates. Also you only have to go through the balancing process for the teardrop washers one time for a particular grinding wheel. Notice the amount of side to side wobble.

If it looks minimal turn on the grinder and observe the side to side wobble at high speed. Easy to setup and use our new balancing system will quickly and easily allow you to balance your grinding wheels for life. In a repositioning operation for compensating for measured unbalance of the grinding wheel the.

Ad Precision Balancing to 50000 pound Spin Testing to 250000 rpm. ONEWAYs balancing operation compensates for.

If you hear a nice tone then the wheel is.

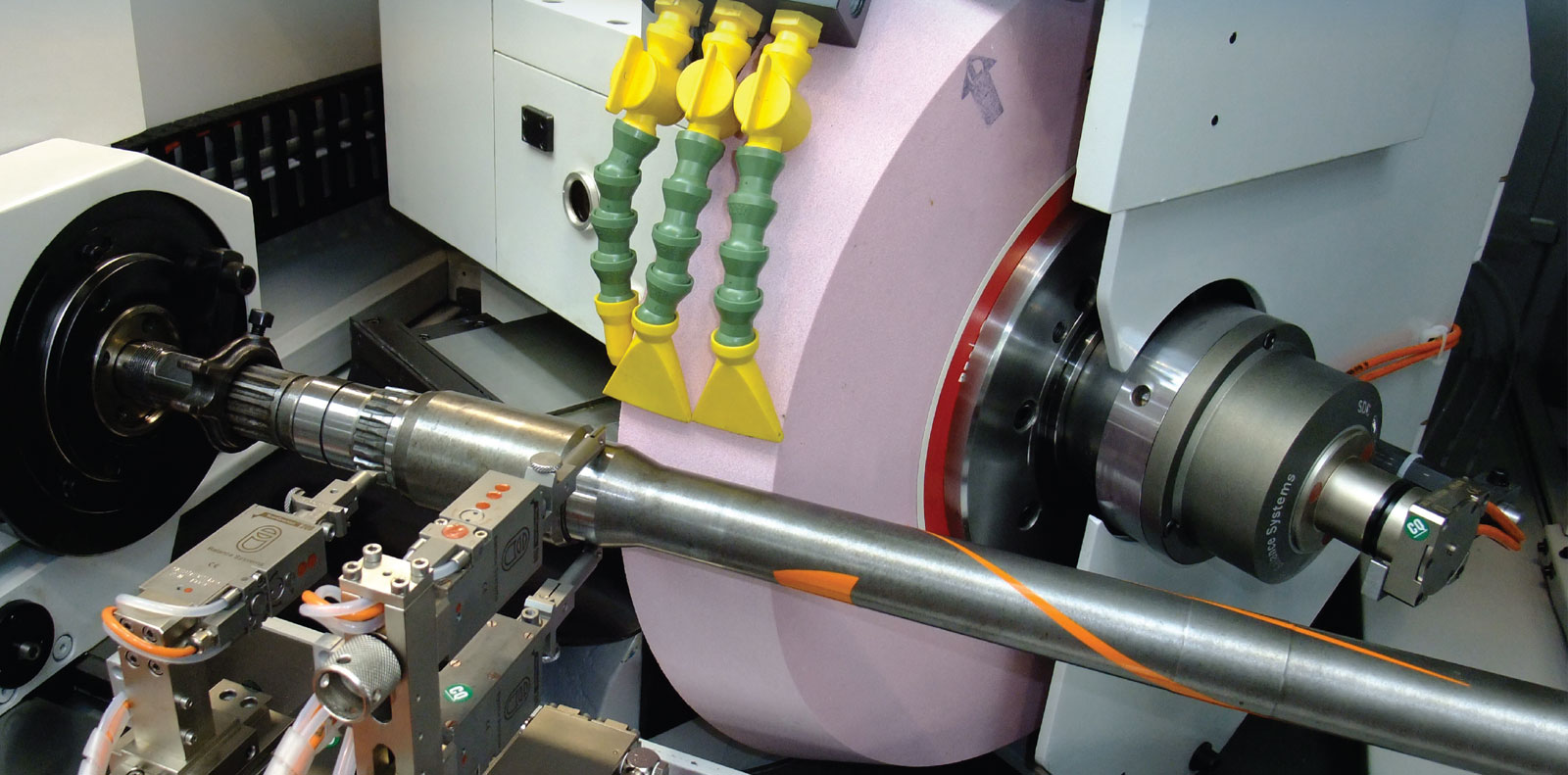

The balancing of the spindle and grinding wheel is an essential operation to achieve the machinings surface quality and to ensure a long life of a rotary components. Ad SB Industrial Supply. Automatic balancing system for grinding wheels The correct balancing of the shaft and grinding wheel assembly is a basic operation for gaining the right surface quality becoming a milestone to achieve excellent results when grinding rubbers or techno-polymers and to dramatically improve the life of the rotational parts bearings shaft motor and grinding wheel. ONEWAYs balancing operation compensates for. Grinding wheels are sensitive to vibration due to their mass and speed. Wheel out of round. Ad Balancing Equipment Engineered For All Applications Parts And Production Rates. Balancing during rotation in one plane with unbalance monitoring. The P7WB system is designed to check and balance the grinding wheels.

Ad Precision Balancing to 50000 pound Spin Testing to 250000 rpm. As the balance state changes constantly due to dressing wear and profiling the balancing of grinding wheels is essential in spite of dressing them. We offer a wide range of balancing systems based on balancing heads which can be installed externally or built-in the spindle. The balancing of the spindle and grinding wheel is an essential operation to achieve the machinings surface quality and to ensure a long life of a rotary components. Position the KP Balancing Ring on the adapter with the logo away from the wheel and the radial setscrew to the light side. Also you only have to go through the balancing process for the teardrop washers one time for a particular grinding wheel. They are a little rattly but they move very freely and in fact work fine to balance a grinding wheel.

Post a Comment for "Grinding Wheel Balancing System"